SMARTXMER

PROACTIVE TRANSFORMER MONITORING

SMARTXMER

PROACTIVE TRANSFORMER MONITORING

SMARTXMER ®

AN IOT BASED PROACTIVE TRANSFORMER MONITORING

At Acumen lotronics Pvt. Ltd., we pioneer loT-based solutions for asset management challenges. Our flagship product, SmartXmer™ , is an IOT based Proactive Transformer

Monitoring System designed to revolutionize how you manage and optimize your transformers.

SMARTXMER™ – PROACTIVE TRANSFORMER MONITORING:

Transform your transformer into a “Smart Transformer” with our plug & play solution. Connect your transformer fleet directly to the cloud, capture real-time data, and receive insights into key operational parameters, ensuring optimal asset usage and proactive maintenance.

WHY SMARTMER™:

Ensure the reliability and safety of power systems with SmartXmer™!

Avoid economic losses, increased maintenance costs, and threats to human life by proactively monitoring critical parameters and receiving real-time alerts.

About Us

PROACTIVE TRANSFORMER MONITORING

Our Vision

It is our vision to work closely with the industry and build a platform that will provide forecasts driven by data and help businesses proactively plan for better operations & maintenance and tackle down times with much ease.

Our Mission

Proactive Monitoring

Address issues before they escalate.

Secure Power Supply

Ensure an uninterrupted flow of electricity.

Cost-Efficiency

Minimise downtime and extend transformer life.

Real-Time Alerts

Swift notifications for immediate action.

KEY FEATURES:

Seamless Support, Endless Possibilities.

A state-Of-the-art proactive Transformer Monitoring Technology – SMARTXMER by Acumen lotronics turns your transformer into “Smart Transformer” !

- Central Data Monitoring through Web-App and Android-App

- Avoid Human Errors with Precise Data

- Real-Time Alerts & Notifications

- Historical Data Digitization and Trend Analysis

- Customized Reports for Effective Monitoring

- Monitoring and Management for Corrective Action

- Device Geotagging

- Seamless Integration with existing equipment

- Total Health Assessment of Transformer

- Proactive Maintenance

A state-Of-the-art proactive Transformer Monitoring Technology – SMARTXMER by Acumen lotronics turns your transformer into “Smart Transformer” !

The SmartXmer – Proactive Transformer Monitoring which will record & analyse key parameter of the transformer and trigger alarms in case of discrepancies of key operation parameters of transformers. The proposed system will capture and display real-time data at user defined intervals and provide with key operational parameters of transformers and indicate the health of the same. This will help utilities to optimally use & maintain their assets and identify problems before any catastrophic failure which can result in a significant cost savings and greater reliability.

Start using the SmartXmer Now!

Our Services

SMARTMER® TECHNICAL DATA SHEET

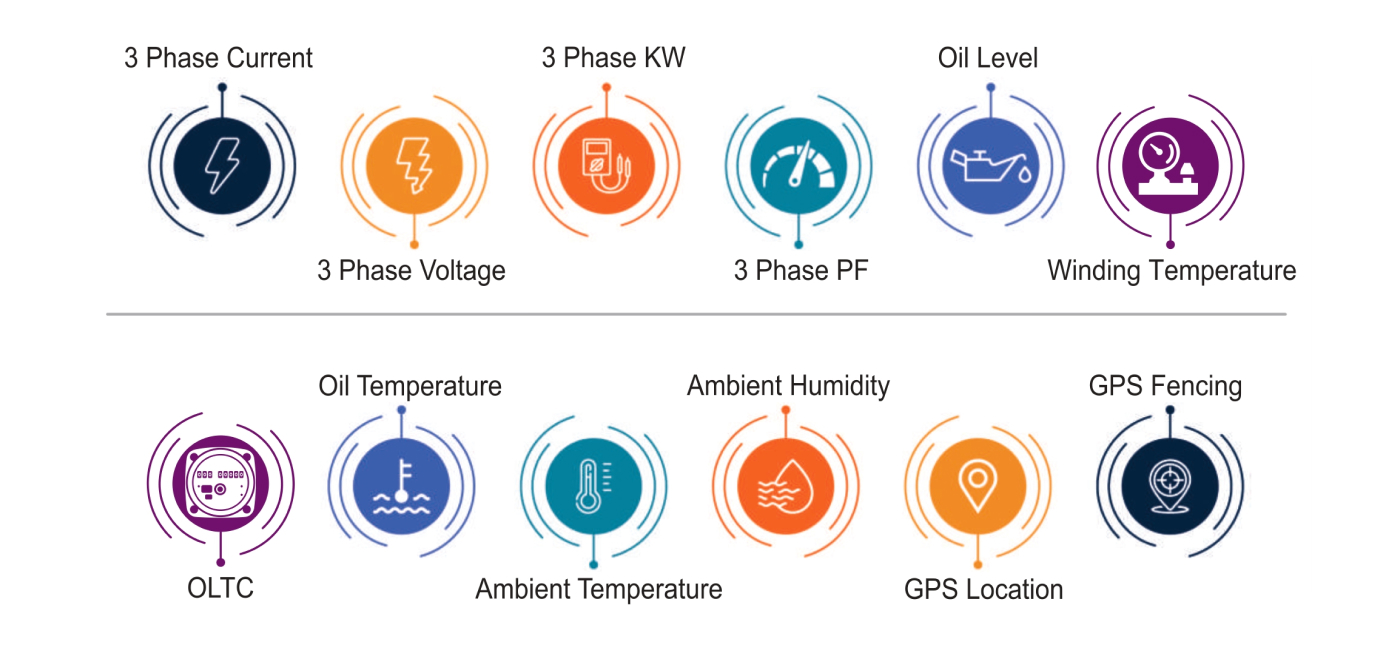

OLTC Tap Counter & Position

Ingress Protection: IP65

Battery Backup upto 2 days

Ambient Temperature

Ambient

Humidity

Energy Parameters

Multiple Input and Output

GPS & Cellular Enabled

Our Partners

Partnering for Exceptional Customer Experiences

Case Study

Stories of Satisfaction and Success

Case Study 1

1. Application – Windmills

2. Transformer – 2500 kVA

3. Asset Cost – Approximately INR 28,00,000

4. Fault Type – Oil Theft, Cable Theft

5. Solution – Transformer Monitoring, Alarms and Tripping

6. Saving Potential

In the event of sudden loss of oil / theft of oil, alarms can be raised for action by the concerned teams.

Since Windmill installations are at isolated locations, reaching the spot in time might not be possible in time. If the transformer stays ON in no oil condition, it might get damaged and lead to loss of asset and surroundings. By the way of Proactive Monitoring with SMARTMER and ability to trip the Transformer, it can be saved from operational damages, thus saving the cost of replacement. In case of repair of such transformers, saving would be cost of repair would be approximately INR 3L and cost of replacement rental for 3-4 weeks of approximately INR 3L. The generation losses of the Wind Mill are additionally estimated at approx. INR 40000 per day.

Case Study 2

1. Application – DISCOMS

2. Transformer – 750 kVA, 1200 Amps

3. Asset Cost – Approximately INR 10,00,000

4. Fault Type – Overloading Condition, High Oil Temperature

5. Saving Potential The failure rate in government utilities is between 15% to 18% in India. And the major factor for these failure are mainly because of over loading of the Transformer which is not monitored by the utility. Continuous high rise in oil temperature and / or overload detection can affect the life of transformer by way of decreasing the winding life, early replacement of Transformers Timely information and guidelines to maintain 70-80% loading will save the replacement costs of the Transformers and prevent revenue losses of DISCOMS. For example if Transformer replacement time is 6 hours, revenue losses for residential application would be approximately INR 6000 per hour that is INR 36000

TOTAL SAVING POTENTIAL FOR 1 INCIDENCE

Asset Repair Cost, Approximately – INR 80,000.

Distribution Revenue Loss – INR 36,000.

In case of Asset Replacement, Cost – INR 10,00,000.